Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 1.83x7m

Brand: Mingyuan

Application: Other

Certification: Other

Customized: Customized

Automatic Grade: Automatic

Material Of Mill Shell: Q235

Thickness Of Shell: 60mm

Diameter Of Cement Mill: 1.8-4.3m

Length Of Cement Mill: 4.5-13m

Installation: Guided By Our Engineer

Lubrication System: Oil Lubrication

Diaphragm Quantity: 2-3

Feed Opening Size: 25mm

Output Size: 200-425 Mesh

Applicable Material: Chemicals, Quartz, Titanium Dioxide

Packaging: Sea worthy packing

Productivity: 28-32 t/h

Transportation: Ocean

Place of Origin: Henan, China

Supply Ability: 2 sets per month

Certificate: CE, ISO

HS Code: 8487900000

Port: Tianjin Port,Shanghai Port,Qingdao Port

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,FCA,CPT

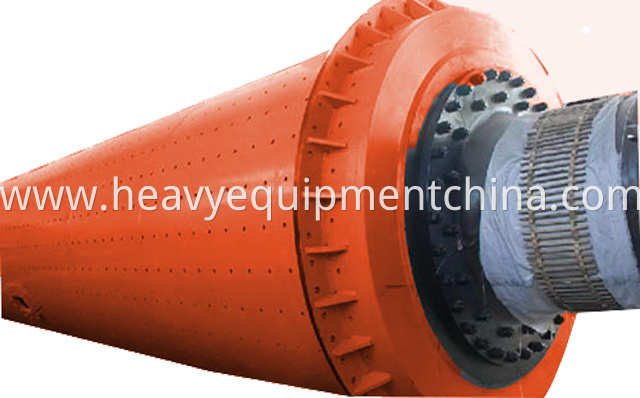

Cement Grinding Ball Mill is also known as Clinker Grinding Ball Mill, Cement Grinding Machine, Cement Ball Mill, which is the key cement grinding equipment in the Cement Manufacturing Equipment and clinker grinding plant, the Clinker Grinding Ball Mill can be divided into two chambers, the first chammber is for the medium size grinding and the second chammber is for the fine particle grinding, after grinding, the powder will be subject to a powder concentrator, from which we get the required particle size.

Cement grinding ball mill, also know as clinker grinding ball mill, it`s a fine powder grinding equipment which is a key grinding machine in cement making plant, the cement mill can be divided into three chambers, after charging different specification of grinding balls, the fineness of the cement is different, the smaller of the grinding ball, the finer powder of the cement, and it also needs a powder concentrator with the Clinker ball mill, the function of the concentrator is to choose the required sizes and the rejected sizes will go back to the clinker grinding ball mill for regrinding, so it applies closed-grinding circuit in the cement grinding plant. our factory can provide different specfications of cement grinding ball mill,

For the components of cement grinding ball mill, it mainly consists of the mill shell, bearing,diaphragm, transmission device(motor and reducer) and lubrication station. It grinds the materials into fine powder mainly by using the impact and grinding force, when the mill rotates, the grinding ball is lifted to some height along with the cement clinker, then the they are dropped down due to the gravity effect, the balls will impact the clinker and break it into smaller particles, and the clinker is ground during it`s lifted to certain height. It will repeat the previous movement until the materials become the required size. Mingyuan can provide different specifications of clinker grinding ball mill for cement grinding plant with different capacities, ranges from 200-5000 t/d

Besides the clinker, the cement grinding ball mill can also be used for the other materials, such as slag, chemicals, coal, quartz, etc.

Technical Parameter of Cement Grinding Ball Mill/Clinker Grinding Ball Mill /ball mill for cement grinding

| Model (D×L) | Rotary speed | Feed size(mm) | capacity (t/h) | ball | Main motor | Main reducer | weight | |||

| Model | Power (kw) | Rotary speed (r.p.m) | Model | Speed ratio | ||||||

| φ2.2×11 | 20.91 | ≤25 | 15~17 | 50 | TR1512-8 | 570 | 740 | Zd80 | 5.6 | 92 |

| φ2.4×8 | 20.91 | ≤25 | 14~18 | 39.5~42 | TRQ1512-8 | 570 | 740 | Zd80-9 | 5 | 76.4 |

| φ2.4×9 | 20.91 | ≤25 | closed 23~25 | 50 | TR1512-8 | 570 | 740 | Zd80-9 | 5 | 91 |

| φ2.4×10 | 20.91 | ≤25 | 16~22 | 50 | TR1512-8 | 570 | 740 | Zd80-9 | 5 | 111 |

| φ2.4×11 | 21 | ≤25 | open 19~24 | 6265 | YR710-8/1180 | 710 | 740 | JDX630 | 5.6 | 125 |

| φ2.4×12 | 21 | ≤25 | open18~20 | 6365 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 127 |

| φ2.4×13 | 21 | ≤25 | open21~22 | 6668 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 131 |

| φ2.6×10 | 20.6 | ≤25 | 21~24 | 64 | YR800-8/1180 | 800 | 740 | JDX710 | 6.3 | 140 |

| φ2.6×13 | 20.6 | ≤25 | 28~31 | 81 | YR1000-8/1180 | 1000 | 740 | JDX800 | 6.3 | 158 |

| φ3.0×9 | 19.13 | ≤25 | 40~45 | 85 | YR1000-8/1180 | 1000 | 740 | MBY800 | 7.1 | 148 |

| φ3×11 | 18.92 | ≤25 | 44~47 | 95 | YR1250-8/1430 | 1250 | 740 | JDX900 | 7.1 | 177 |

| φ3×12 | 18.92 | ≤25 | 48~52 | 103 | YR1250-8/1430 | 1250 | 740 | JDX900 | 7.1 | 182 |

| φ3×13 | 18.92 | ≤25 | 39~45 | 116max | YR1400-8/1430 | 1400 | 740 | JDX900 | 7.1 | 200.7 |

Our service for Cement Grinding Ball Mill/Clinker Grinding Ball Mill /ball mill for cement grinding

1) Installation and guidance

When the machine arrives at your company, we will dispatch our technicians to your company to guide the installation and commissioning at site. User should pay for the following fees air tickets, boarding and lodging and traffic in client's factory.

(2)Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

(3)Warranty

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service.

Product Categories : Cement Manufacturing Equipment > Cement Ball Mill

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.